Interface Auto is dedicated to ensuring the reliability and performance of our products through rigorous validation processes. We employ cutting-edge testing methodologies to simulate real-world conditions, guaranteeing that our components meet and exceed industry standards. Our comprehensive validation protocols include environmental, mechanical, and electrical testing, ensuring durability and safety. By prioritising thorough product validation, we provide our customers with the confidence that our solutions are built to withstand the demands of the automotive industry, ensuring long-term performance and satisfaction.

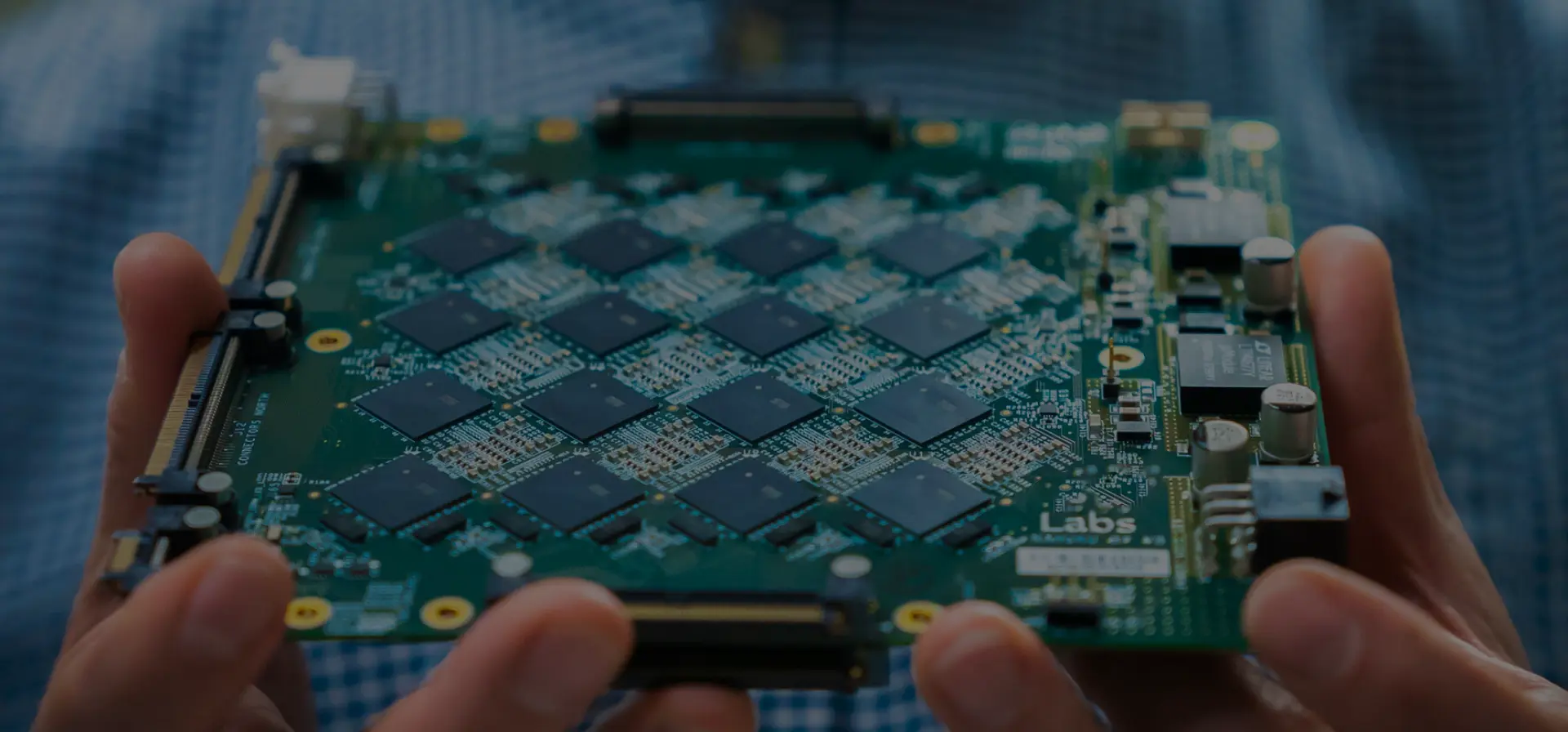

We have invested into a self-sufficient in-house lab facility for carrying out Design Validation plans in compliance to latest ISO, JASO and SAE standards for electrical, environmental and mechanical tests for both 12V and 24V systems.

Our test facility is regularly audited by our OEM customers and is well maintained in timely manner in close liaison with equipment manufacturer. We keep upgrading and investing into our Test lab facility based on emerging needs from time to time. A dedicated team of expert test engineers

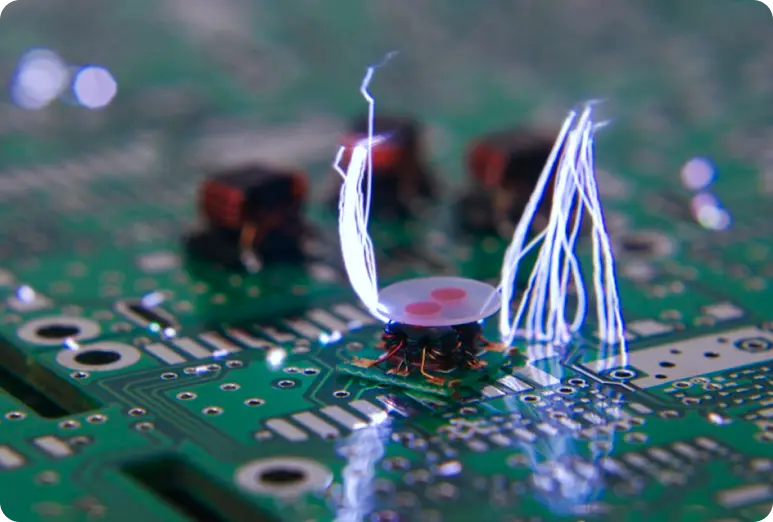

Electrical

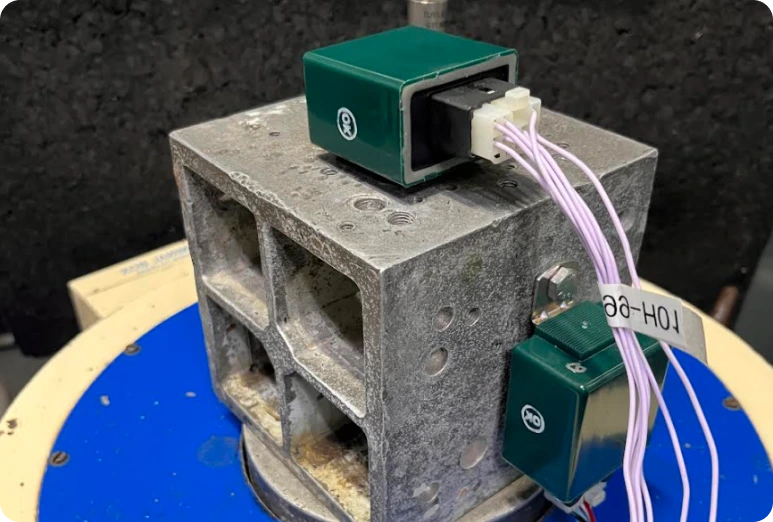

Mechanical

Environmental

Endurance